I was going to post something different today, but it involved gold leaf and I started to become curious as to just how gold leaf is made. One thing led to another and here we are, we sharing everything I've found with you all.

I enjoy many traditional Japanese arts, but doing some of them myself as a hobby and watching masters do others. Seeing as how many traditional crafts end with using gold leaf, I have always had some small idea of how it is made, but never more than that. After a deep dive lasting a few hours, I have a much better idea!

via Wikipedia

Almost all gold leaf production in Japan, nearly 99% of it, is done in Kanazawa. That's the capital city of Ishikawa, by the way, the place where the recent New Year's earthquake was. Kanazawa (金沢) literally means "marsh of gold" in fact.

The craft of making gold leaf is thought to have started in Egypt around 2600 BCE. From there it spread to China and then eventually to Japan. It made its way to Kanazawa by 1593 and quickly became very popular there.

There are two kinds of gold leaf in Japan: entsuke and tashikiri. The former is the traditional way, layering it with a special washi paper and pounding it repeatedly until it is just .1 micron thick. It takes a master about two weeks to make 100 sheets using this traditional method. Well, some don't do it entirely the old way; they sometimes use machines to do the pounding instead of doing that by hand, ensuring both that the pressure used is more regular and saving them the manual labor.

Tashikiri by contrast was developed in the 1960s and uses modern methods. It allows gold leaf to be mass produced and therefore more inexpensive. But y'know, it's not nearly as attractive to us as the traditional way.

Watch it being made:

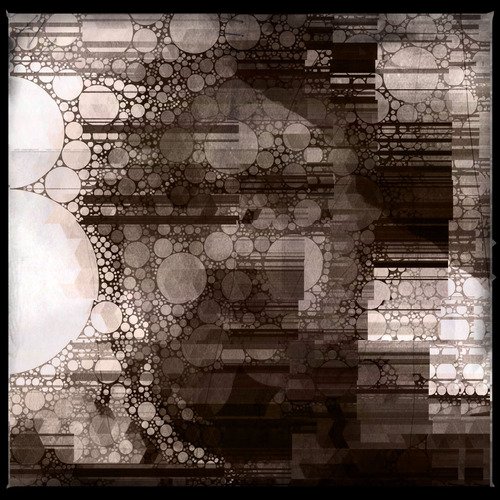

At the end of the video you can see a man using sheets of gold leaf on a Buddhist temple carving. It takes a lot of sheets for just a small carving. How many do you figure it takes for a much larger job, like, say, Kinkakuji in Kyoto?

Thousands? More? - via Wikipedia

It's not pure gold. They begin with pure gold (or as pure as they can get, I suppose) and mix it with a tiny amount of silver and copper. According to Wikipedia the exact mixture is 94.43% gold, 4.9% silver, and 0.66% copper. They melt it all, then stretch the resulting alloy between metal rollers to get the initial thin piece. Then they begin the hammering process.

It is then placed in that stack of washi you see in the video. The paper is handmade from pulp using fine clay and the fibers of a plant called ganpi. The paper itself, called hakūchi paper, takes awhile to make. It is left to moisten overnight in some water, then beaten to ensure the moisture is even throughout the paper; they are then peeled apart, allowed to dry. This process can be repeated many times to ensure a uniform quality. They are then bundled and soaked in a mixture of lye, persimmon juice, egg yolk, and egg whites, then this mixture is mixed with ash from burned straw. After the paper bundles have absorbed enough of the mixture, they are wrung out, dried, peeled apart, dried and beaten again, then finally assembled into a stack of paper for making the gold leaf.

Making the paper takes longer than the gold leaf, about six months to a year. It is the most important part, because if the paper is made badly then the gold will stick to it and won't stretch very well when pounded, and will also tear. It is said that 90% of the skill in making gold leaf is making the paper.

Gold leaf is extremely important to Japan's traditional buildings, like Kikakuji as you see above, and crafts. And it is still produced almost entirely in one place. Wow!

The process of applying it is then takes another expert!

But anyway, we'll stop here. Pretty interesting stuff.

❦

|

David LaSpina is an American photographer and translator lost in Japan, trying to capture the beauty of this country one photo at a time and searching for the perfect haiku. He blogs here and at laspina.org. Write him on Twitter or Mastodon. |